Case Study – Calenzano

In this new section, we will present you some valuable and informative case study from our customers.

The first case study we will present you is kindly provided by Microgeo, our exclusive Italian reseller for 3DF Zephyr Aerial. Microgeo is a leading topography and geomatic provider, that offers complete solutions for survey and measurements, hardware and software, from photogrammetry to laser scanners and drones.

The dataset we will show you today is from Calenzano, a small Village in the region of Tuscany, near the city of Florence, Italy.

The dataset has been processed with 3DF Zephyr Aerial and took using:

- Reflex Camera SONY DSC-QX30

- Drone Zenmuse X5S Camera DJI FC6520

- Laser Scan Faro

The goal of this project is to show how the power of 3DF Zephyr allows you to merge different survey methods such as ground pictures, aerial pictures, and laser scan.

The dataset has been also used to create the highlights feature video for version Zephyr 4.0.

Survey:

For this purpose, Microgeo’s surveyors took :

- 28 ground pictures of the church facade

- 721 aerial pictures (~50 m from ground)

- 1 cleaned laser scan cloud (church facade)

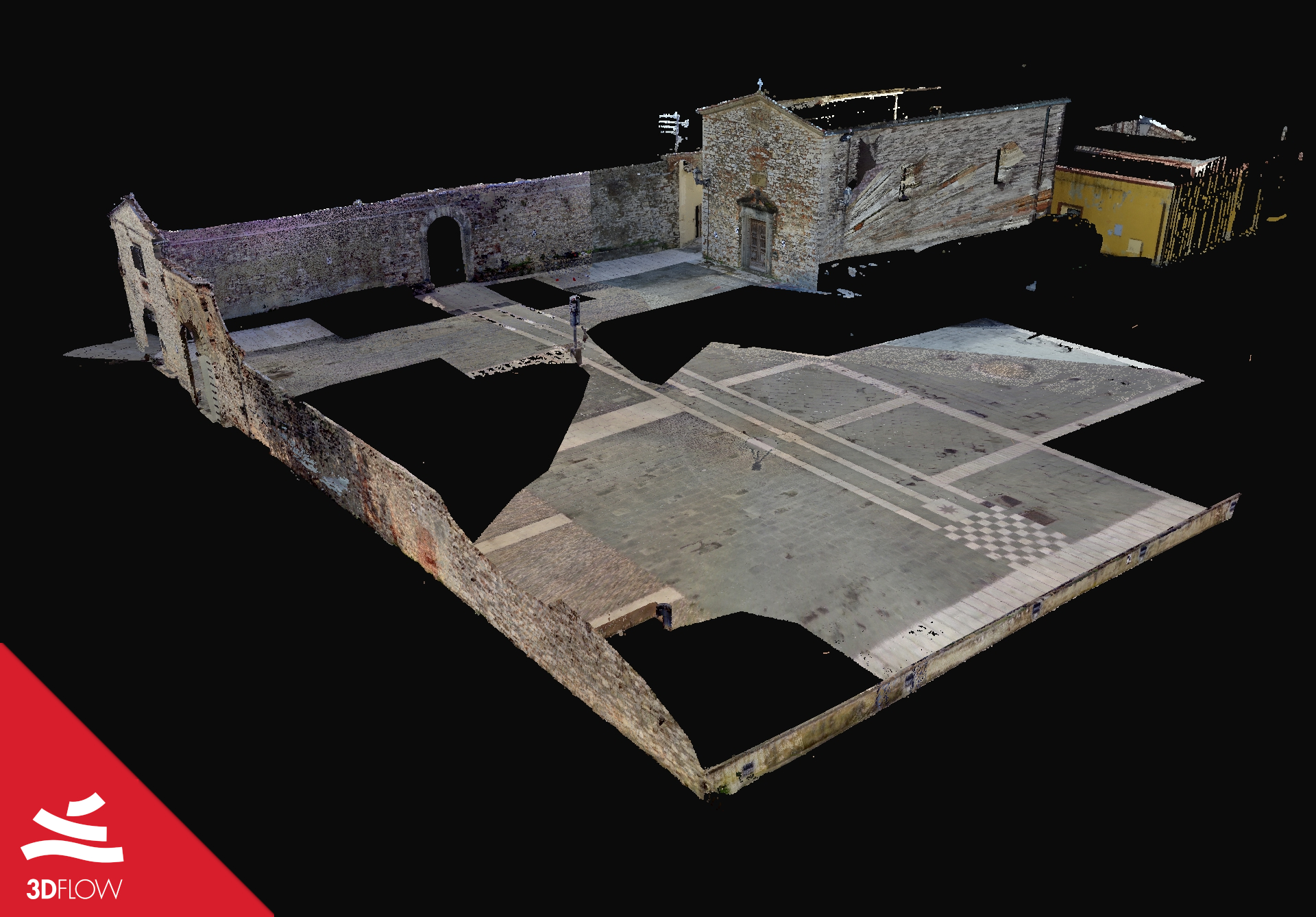

These are the resulting point clouds :

Figure 1. Point Cloud generated with aerial photos, 18.870.601 points.

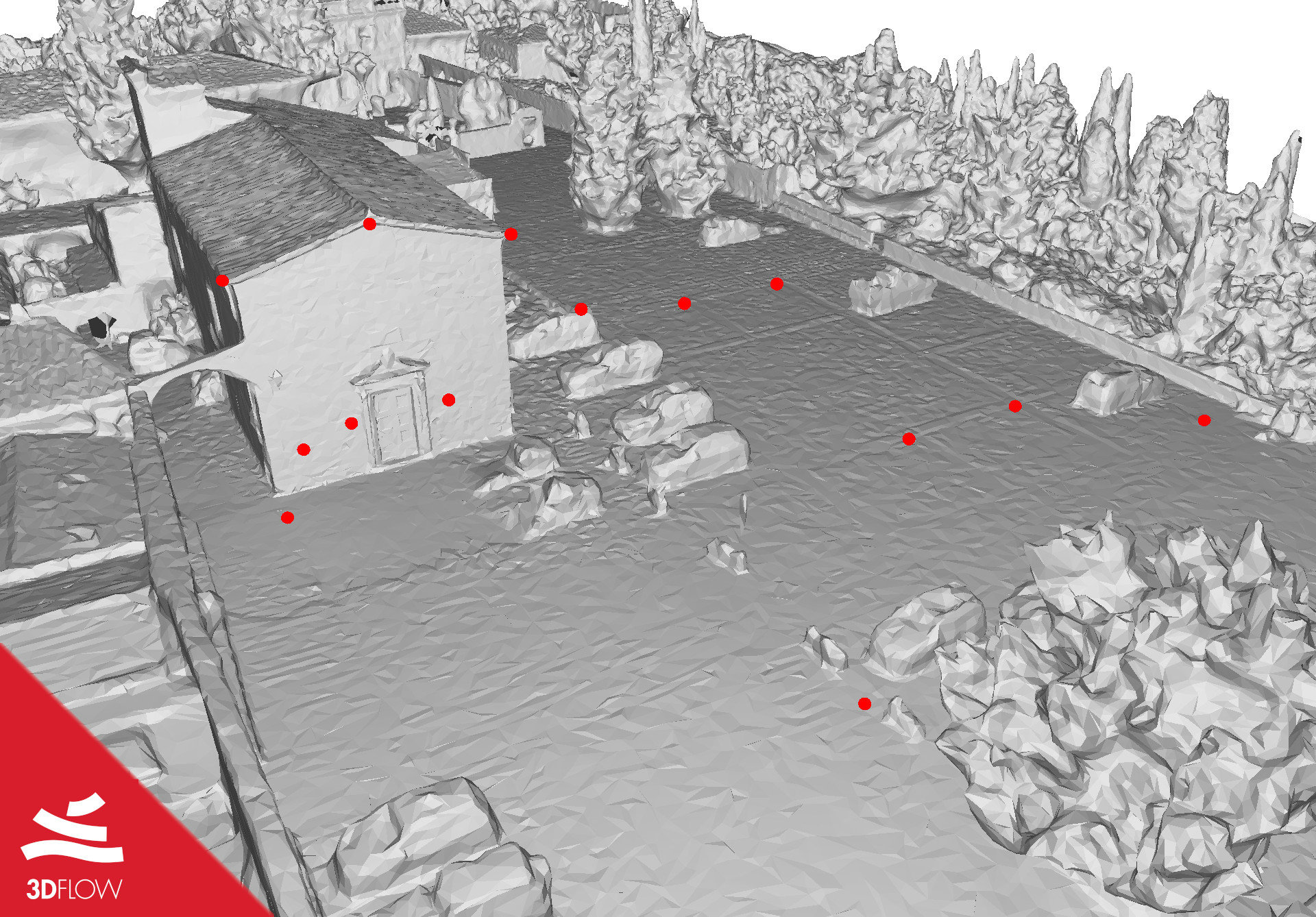

Figure 2. Point Cloud generated with laser scan.

Workflow :

Control points were used to merge the 3DF Zephyr workspaces generated with Photogrammetry and Laser-Scan.

To do this, they have been set :

- 12 Ground Control points (device: Zenith 15 GNSS, 1.5cm accuracy)

In particular

- 6 control points as constraint

- 6 control points used as control

| POINT | RESIDUAL | X RESIDUAL | Y RESIDUAL | Z RESIDUAL |

| 100 | 0.0132051 | 0.00522232 | -0.00164603 | -0.0120163 |

| 101 | 0.0362699 | 0.0048722 | 0.000111115 | 0.035941 |

| 102 | 0.0327985 | -0.00182664 | -0.0320546 | 0.00670175 |

| 103 | 0.0383704 | 0.0321385 | -0.0145861 | -0.0150548 |

| 104 | 0.013715 | -0.0129768 | -0.00230127 | -0.00379576 |

| 105 | 0.0507758 | -0.0382977 | 0.0199403 | -0.0267181 |

| 106 | 0.0460916 | -0.0305928 | 0.033015 | 0.00992598 |

| 107 | 0.0163361 | -0.00500572 | -0.0132391 | -0.00815699 |

| 108 | 0.0203802 | 0.0131803 | -0.0155389 | -0.000420849 |

| 109 | 0.0496088 | 0.0129072 | -0.0472074 | -0.00811763 |

| 110 | 0.0582333 | -0.000139036 | -0.000406915 | 0.0582318 |

| 111 | 0.0418537 | 0.00703028 | 0.0369087 | -0.0184407 |

| 112 | 0.0433378 | 0.0134879 | 0.0370051 | -0.0180794 |

Here a screenshot of control points taken:

Figure 3. Overview of control points.

They proceeded then with the merge of workspaces using control points as merge method and also performing another bundle adjustment as an additional option.

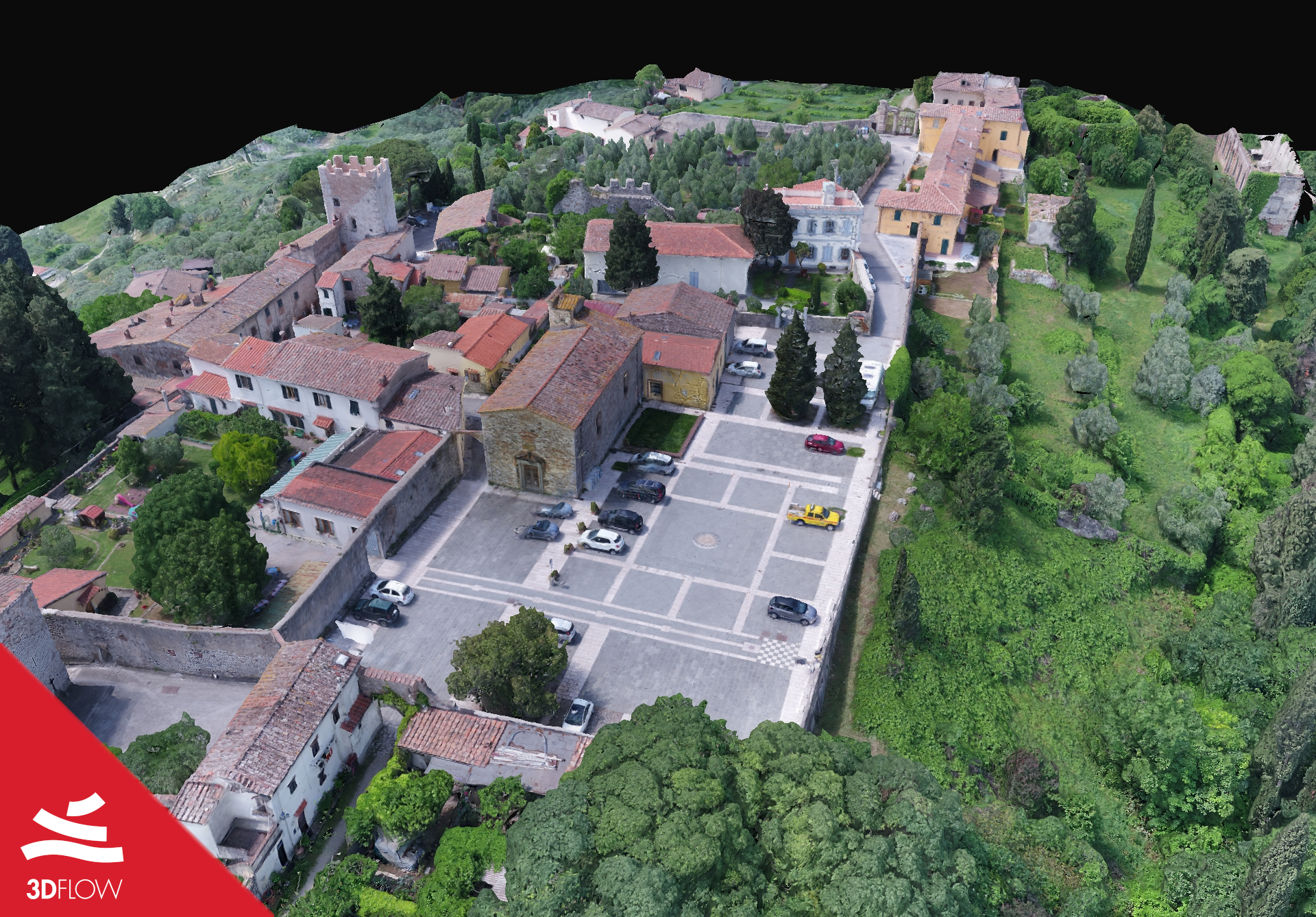

And here is the final results:

Figure 4. Textured mesh resulted of Photogrammetry and Laser Scan merge.

This case study showed an example of aerial images and laser scan integration. Please contact us if you have any feedback or want to write a showcase article on the 3dflow.net website!